In the realm of industrial equipment, the quest for optimal thermal management solutions has reached new heights with the advent of the best Kaltra Microchannel Heat Exchangers. Renowned for their engineering precision and cutting-edge design, these heat exchangers represent the pinnacle of efficiency and performance in industrial thermal solutions. In this article, we will delve into the key features, applications, and advantages that make the best Kaltra Microchannel Heat Exchangers stand out as indispensable components in modern industrial processes.

-

Key Features of the Best Kaltra Microchannel Heat Exchangers

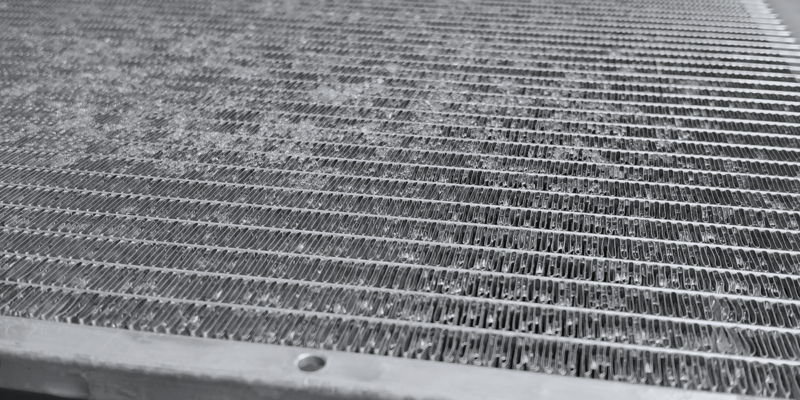

Engineering Precision: The best Kaltra Microchannel Heat Exchangers are characterized by engineering precision. Meticulous design, leveraging advanced computer-aided design (CAD) technologies, ensures an optimal arrangement of microscale channels, contributing to superior heat transfer efficiency.

Materials Excellence: These heat exchangers utilize high-grade materials, such as advanced aluminum and copper alloys, known for their exceptional thermal conductivity. The choice of materials contributes to the durability, reliability, and overall performance of the heat exchangers.

Compact Design: The best Kaltra Microchannel Heat Exchangers are engineered with a focus on space efficiency. The microscale channels allow for a higher surface area-to-volume ratio, resulting in a compact and lightweight design without compromising thermal performance.

Turbulent Flow Promotion: Achieving turbulent flow within the microchannels is a key feature of the best Kaltra Microchannel Heat Exchangers. This characteristic enhances convective heat transfer, leading to significantly improved overall heat transfer efficiency.

-

Applications Across Industries

Automotive Cooling Systems: The best Kaltra Microchannel Heat Exchangers play a crucial role in automotive cooling systems. Their efficiency in dissipating heat generated by engines and electric vehicle batteries contributes to improved overall vehicle performance.

Electronics Cooling: In the electronics industry, where heat management is critical, the best Kaltra Microchannel Heat Exchangers prevent overheating, ensuring the longevity and reliable performance of electronic components in various applications.

HVAC Systems: The compact design and enhanced heat transfer capabilities of the best Kaltra Microchannel Heat Exchangers contribute to energy efficiency and improved overall system performance in heating, ventilation, and air conditioning systems.

Renewable Energy Applications: These heat exchangers are integral components in various renewable energy systems, including solar thermal and geothermal applications. Their efficiency in transferring heat is essential for harnessing and utilizing sustainable energy sources.

-

Advantages of the Best Kaltra Microchannel Heat Exchangers

Optimal Heat Transfer Efficiency: The advanced design and turbulent flow promotion in the best Kaltra Microchannel Heat Exchangers result in optimal heat transfer efficiency. This is crucial for industries where precise temperature control and rapid heat exchange are essential.

Space Optimization: The compact nature of the best Kaltra Microchannel Heat Exchangers allows for efficient space utilization. This is particularly advantageous in industrial settings where available space is limited, enabling versatile integration into diverse systems.

Durability and Reliability: The use of high-quality materials ensures the durability and reliability of the best Kaltra Microchannel Heat Exchangers. This is essential for industries that demand robust and long-lasting thermal management solutions.

Energy Efficiency: In HVAC systems and other applications, the best Kaltra Microchannel Heat Exchangers contribute to energy efficiency. Their enhanced heat transfer capabilities lead to reduced energy consumption, aligning with the broader push for sustainable industrial practices.

-

Considerations for Choosing the Best Kaltra Microchannel Heat Exchangers

Application-Specific Requirements: Different industries have unique thermal management requirements. Choosing the best Kaltra Microchannel Heat Exchangers involves considering the specific needs of the application, including temperature ranges, flow rates, and space constraints.

Materials Compatibility: Ensuring compatibility with the fluids and materials involved in the industrial process is crucial when selecting the best Kaltra Microchannel Heat Exchangers. This consideration contributes to the longevity and effectiveness of the heat exchanger in specific applications.

Customization Capability: The best Kaltra Microchannel Heat Exchangers often offer customization options to meet the diverse needs of industries. This allows for tailoring the heat exchangers to specific requirements, ensuring optimal performance.

-

Conclusion

In conclusion, the best Kaltra Microchannel Heat Exchangers represent the epitome of excellence in industrial thermal management. Their advanced design, materials excellence, compact nature, and superior heat transfer efficiency make them indispensable in various applications across industries. As industries continue to prioritize efficiency, reliability, and sustainability, the adoption of the best Kaltra Microchannel Heat Exchangers is poised to drive innovation and elevate the standards of industrial thermal solutions.

Comments